1. MT doweling jig the first tool that we're going to talk about today was designed specifically for people who work with wood in furniture production there is something known as a dowel it is a fixing wooden element sometimes with a grooved surface which has an elongated cylindrical shape it is inserted into the holes made in wooden parts to connect them to each other the main difficulty during this process

is making the holes they must have the same depth the diameter and distance

between each other MT doweling jig from the American company woodpeckers is a specialized tool to make drilling holes easier and faster the metal part is attached to the wooden element to the side after that

all that's left is drilling through the template by the way despite the fact that there are only three holes the tool is also useful in situations where you need to drill a large number of holes in this case the template is simply slid to the side and then fixed to the already drilled hole with a special screw mt jolly dig is available for a hundred and fifty dollars.

2.

Dewalt dust extractors almost any work with a driller perforator involves a lot of dust the problem is that dust is harmful to humans impairs visibility and after the work is done you have to clean up the mess the tool you see on the screen is an effective solution to that problem offered by the American brand Dewalt it's specialists have developed avariety of products designed to minimize the amount of dust on the construction site the set of products is individually selected for each working tool we are now looking at a dust extraction system designed to work with large drills this is a construction vacuum cleaner with the capacity of almost 4 liters the dwv 0:12 model is suitable for both dry

and wet cleaning the cleaner works in conjunction with the DW h 0 v 0 k attachment it is a system for dust extraction as well as hole cleaning it comes with two drilling heads one is suitable for holes up to 2.5 centimeters in diameter the other one is suitable for holes up to 5 centimeters thanks to the rubber seal the head fits securely on any surface including vertical ones.

3.

Northstar soft wash system regular viewers of our channel already know what

a high pressure washer is what you see on the screen is a similar tool but alsoban alternative for an easier way to deal with dirt the Northstar soft wash system from the American brand Northern Tool and equipment is suitable for cleaning roofs walls roads concrete pavement fences and in general almost all surfaces on the street when compared tovhigh pressure washers the system stands out for not using high pressure but in this case it is more an advantage than a disadvantage because the operator during the work has to apply much less effort in addition the jet acts gently on the surfaces without damaging them another key difference is the liquid that is used for the cleaning Northstar soft

wash uses a special solution that combines bleach water and a special detergent this combination does not simply wash away mold the bacteria the solution literally kills them maintaining the

surface clean for much longer Northstar soft wash can also handle dust dirt allergens and any organic stains by the way the length of the jet reaches 9 meters thanks to this the operator is able to clean the roof without using a ladder

4.

DR walked behind leaf facts and here is

another interesting tool which will be useful not only for professional workers

but also for ordinary people who live in

houses with a yard removing leaves can

be a long and tedious task and buying a

garden vacuum like this from done right

solves the problem instantly and at the

same time saves a huge amount of time

there are several models of vacuums with

slightly different power and capacity all models are however quite compact in size

the equipment's width allows it to not get stuck in gates but thanks to the two rear wheels the vacuum cleaner is able to rotate around its axis this makes it quicker and easier to remove the leaves from under the trees inside the vacuum cleaner the leaves are shredded very carefully this reduces the volume they take up by almost 10 times and allows you to work longer beforebemptying the tank.

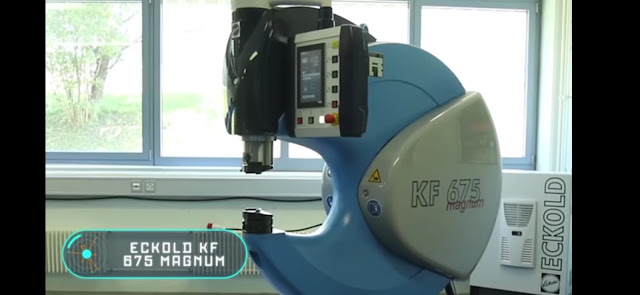

Ecold KF 675 Magnum now let's talk about something that is used in professional production workshops here is the metalworking machine developed by specialists of the Swiss company Eccles

this machine is capable of bending profiles shaping sheet metal and producing various parts from scratch besides it can easily deal with repair works and in skilled hands it will be suitable even for fine adjustment works such equipment is in demand of factories that make parts for shipyards in

aviation working with the KF 675 Magnum

is very easy so specialists also choose it to restore vintage cars for example the wide range of tool bits allows you to use this equipment for all kinds of work and the fact that it runs quietly and doesn't make a mess only proves how technological and well-designed it is.

6.

pas pro pedal broom you may have already decided that all the efficient cleaning tools are very complex that's not always true for example pas Pro pedal is an electric broom with high performance and a fairly simple design the manufacturer decided to make the broom really powerful the result is a tool that can

sweep away even large heavy and complex

debris such as stones acorns nuts combs

and pine needles and seconds at the same

time there is no damage to the soil or grass itself the pas pro petal broom is

a development of the American company

echo an additional advantage is as large

working width of 55 centimeters interestingly it can also be used with a garden trimmer.

7.

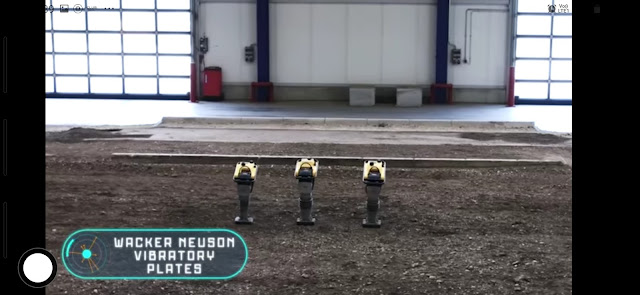

Wacker noise and vibratory plates the last tool we will show you today brings us straight back to the construction

site you probably know that before you

start laying asphalt or finishing any other surface the workers have to carefully prepare the ground this includes leveling as well as compacting the surface in more complex terms it's binding the soil particles together as a result the terrain is more even which guarantees the longevity of the future coating vibratory plates are the right equipment to perform the described procedure the video shows a device developed by vaca moisten the company's products range includes a huge number of models for example there are diesel gasoline and electric grammars for

stroke and two-stroke models the first one stand out for the productivity and higher amplitude vibrations the working speed of the tools varies from seven to nine meters

per minute the number of blows per minute can reach 650.

If you like our articles please keep support us & flow with email for free ..... thank you